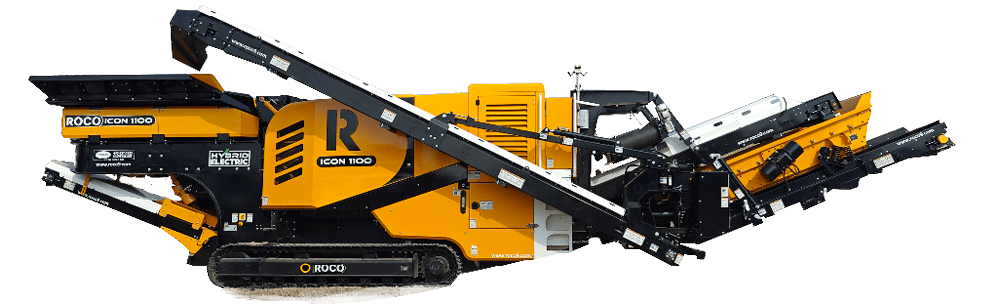

Meet SPRINTER 1500

POWERING FORWARD

with Hybrid Efficiency

Established 2023. The SPRINTER 1500 is winning the screening race with two patent-pending features and unmatched scalping performance. It’s the fastest, most aggressive compact mobile scalper in its class, delivering a wide range of operating speeds and adjustments. In under a minute—and with zero manual labour—the SPRINTER 1500 converts from a 3-product to a 2-product machine (2/3-way split). Fully electric-drive with plug-in option, it’s exceptionally versatile for contractors, indoor recycling centres, and wash plants.