Meet RYDER 1000

POWERING FORWARD

with Hybrid Efficiency

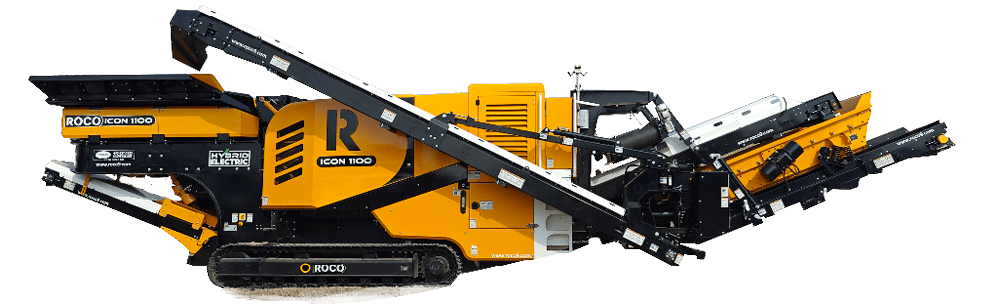

Established in 2020, the Roco RYDER 1000 was the first machine fully designed and built by ROCO in N. Ireland. It has since earned its place on sites across 15+ countries, praised for its simplicity, power, and unmatched fuel efficiency.

Built around operator needs, the RYDER 1000 combines diesel-electric power, rapid setup, and easy transport, without the need for special movement permits across the EU. It handles the hardest granite and the dirtiest demolition waste with ease, setting new standards for uptime and performance in the 30-ton class.